After the boiler is used for a long time, it will bring problems such as scaling, slag accumulation, and blockage of the pipe wall, resulting in the reduction of heat transfer efficiency, the increase of exhaust back pressure, and the further corrosion of the pipe caused by the sulfur in the soot adhering to the pipe wall.

The most commonly used cleaning methods are high-pressure water jet physical cleaning and chemical cleaning:

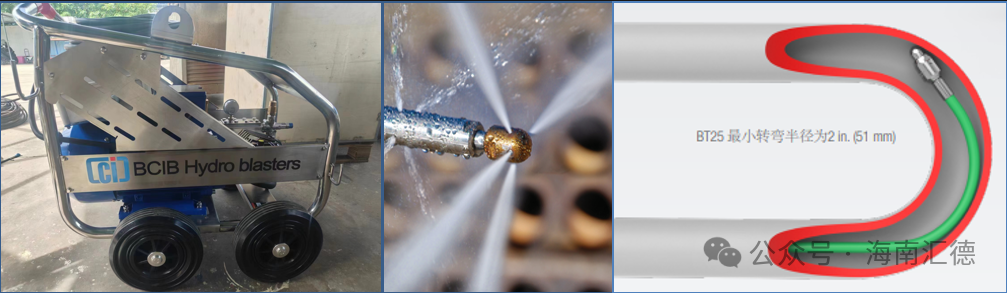

▍ Water jet physical cleaning

Principle: High-pressure water jet descaling is to use the impact effect of high-pressure water jet and water skid to destroy the adhesion of scale to the substrate. It is to use water as the medium to drive a high-flow supercharger through a diesel unit or a motor unit, pressurize the water to the required pressure, and then spray it through a plurality of gem nozzles arranged in a circle to form a multi-beam, multi-angle, high-pressure rotating water jet with different intensities, which has a very high energy absorption density, and carries out erosion, denudation, excision, and peeling impact on the dirt object to achieve the purpose of descaling.

▍Technical features

1. The water jet uses the water skid action to separate the dirt from the substrate, so it will not damage the substrate of the object to be cleaned.

2. The high-pressure water jet will not cause secondary pollution, and there is no need for cleaning treatment if there are no special requirements after cleaning.

3. When cleaning objects with complex shapes and structures and fully blocked pipelines, you can choose specific accessories to go deep into the dirt position to clean accurately, which can achieve fast and thorough cleaning. For example, the cleaning rate of the heat exchanger is more than 100%, and the descaling rate of the boiler is more than 100%.

4. Only ordinary fresh water is used for pressurization operations, so the high-pressure water jet is highly permeable, and can remove salt, rust, and water-soluble chloride more thoroughly and deeply.

▍ Technical shortcomings

1. When high-pressure water jet cleans special profiles or inner walls with a particularly large pipe diameter span, special accessories and nozzles are required to clean them.

▍Chemical cleaning

Principle: Chemical cleaning is a method that relies on the action of chemical reaction and uses chemicals to remove dirt on the surface of objects. Usually, an appropriate amount of corrosion inhibitors and additives for activation, penetration and wetting should be added to the chemical cleaning solution. Circulating chemical cleaning is to connect the device pipeline equipment and the cleaning pumping station into a loop to form a circulating system, add a certain concentration of cleaning liquid, circulate and clean in the pipeline, so that the cleaning liquid and the inner wall of the container are in full contact, and the chemical reaction occurs to meet the requirements of the cleaning equipment and continuously replenish the cleaning solution when the concentration of the cleaning solution drops to a certain extent.

▍Technical features

1. For a single dirt cleaning effect is better.

2. High compatibility with profiles of the opposite sex.

▍ Technical shortcomings

1. When the scale is very thick or the pipeline is blocked, because the cleaning liquid is not circulated in place, it cannot react with the dirt and cannot meet the cleaning requirements;

2. Clean different scales, the degree of scaling needs to use different types, different concentrations of chemicals, for complex mechanical mixtures or scales with multiple components, such as polymer grease, paraffin, asphalt, polymerization precipitate or coke, etc., the composition of chemical agents is difficult to test, so it is difficult to clean by chemical methods;

3. The chemical agent has acid-alkali characteristics, which has a certain corrosive effect on the substrate to be cleaned, and the wall thickness of the substrate is reduced during cyclic cleaning, which causes the stress rupture of the substrate in the long run;

4. The acid and alkali emissions in the chemical cleaning operation are seriously polluting to the environment;

5. Chemical cleaning requires a large number of acids and slow-release agents, especially for large-diameter pipelines and large containers, and the amount of chemicals required is huge, and the cleaning cost is high;

6. It needs to be soaked and circulated for a long time, and the cleaning efficiency and cleanliness rate are low.

Hainan Huide solution: Introduce water jet physical cleaning into the cleaning of marine boiler tube bundles, and penetrate deep into the boiler tube bundles for thorough cleaning through imported high-pressure water pumps with different types of nozzles.