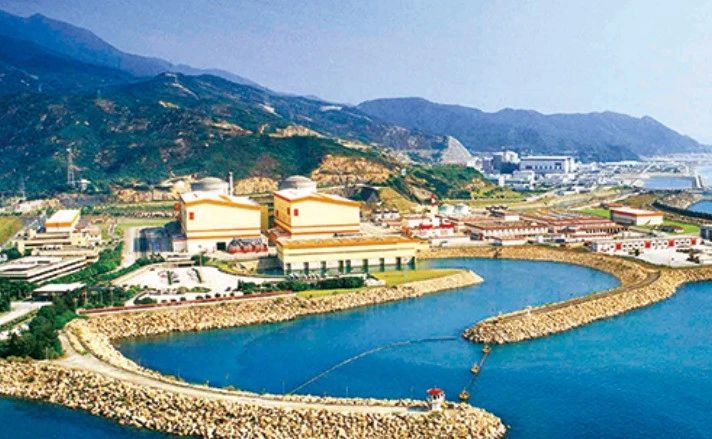

The water inlet of the nuclear power plant is provided with a water inlet grid, and in the seawater environment, the grid needs to be regularly treated with anti-corrosion treatment to ensure the lifespan; The first step of anti-corrosion is to completely remove dirt, marine life, rust and paint from the surface of the grille; How to carry out surface treatment with high efficiency and high quality is the first key link in the anti-corrosion construction of the grille.

Based on years of experience in the application and promotion of ultra-high pressure water surface treatment technology, our company recommends the use of ultra-high pressure water for surface treatment of the grille, which has relative advantages compared with other operation methods.

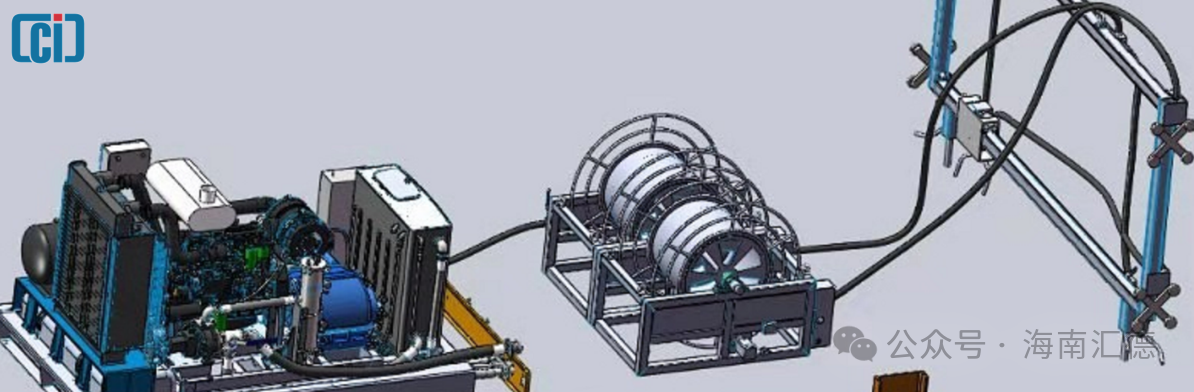

▲The above is our company's ultra-high pressure water anti-corrosion project of a nuclear power inlet grid in September 2019

Water inlet grille chute cleaning

The inlet grid of the nuclear power inlet should be installed in the inlet grid trough, and in the seawater environment, the grating trough will be attached to marine organisms, which will hinder the positioning and movement of the grate, and it needs to be cleaned regularly. Traditional cleaning solutions require divers to work underwater, which is extremely risky and inefficient.

Hainan Huide has customized and developed a set of automatic cleaning mechanism for the structure of the nuclear power grid groove. The use of high-pressure water and the automatic cleaning mechanism does not require divers to enter the water for underwater operation, which greatly improves the safety and efficiency of the operation.

The inlet grating chute cleaning system is a kind of equipment specially designed to clean the inlet grating and chute in hydroelectric power stations, sewage treatment plants or other water treatment facilities.

Such a system usually consists of the following main components:

Ultra-high-pressure water machine system: This is the core part of the cleaning system and is responsible for generating a high-pressure water flow. The system typically includes one or more high-pressure pumps capable of pressurizing water to hundreds or even thousands of bars to generate enough impact to wash dirt and sediment from the grilles and chutes.

Ultra-high-pressure piping system: This part is responsible for the safe and efficient delivery of the high-pressure water flow generated by the ultra-high-pressure water machine system to the cleaning actuator. Piping systems need to be able to withstand the pressure of high-pressure water flows, are typically made of special materials such as steel or high-strength plastics, and may include a variety of fittings, valves, and quick connects.

Customized actuator: This is the part that is in direct contact with the surface to be cleaned and is responsible for directing the high-pressure water flow to the target area. Actuators may include a variety of nozzles, guns, or cleaning heads, which can be customized to the specific requirements of the cleaning task. For example, some nozzles may be designed to create a specific water flow shape or pattern to remove different types of dirt more effectively.