01

Problems after long-term use of boilers

Marine boilers are an important part of the ship's power system. After long-term operation, problems such as tube wall scaling, slag accumulation and blockage will occur inside the tube bundles. These problems lead to reduced heat transfer efficiency, increased exhaust back pressure, and further corrosion of the pipeline caused by the adhesion of sulfur in the soot to the pipe wall, seriously affecting the operating efficiency and life of the boiler.

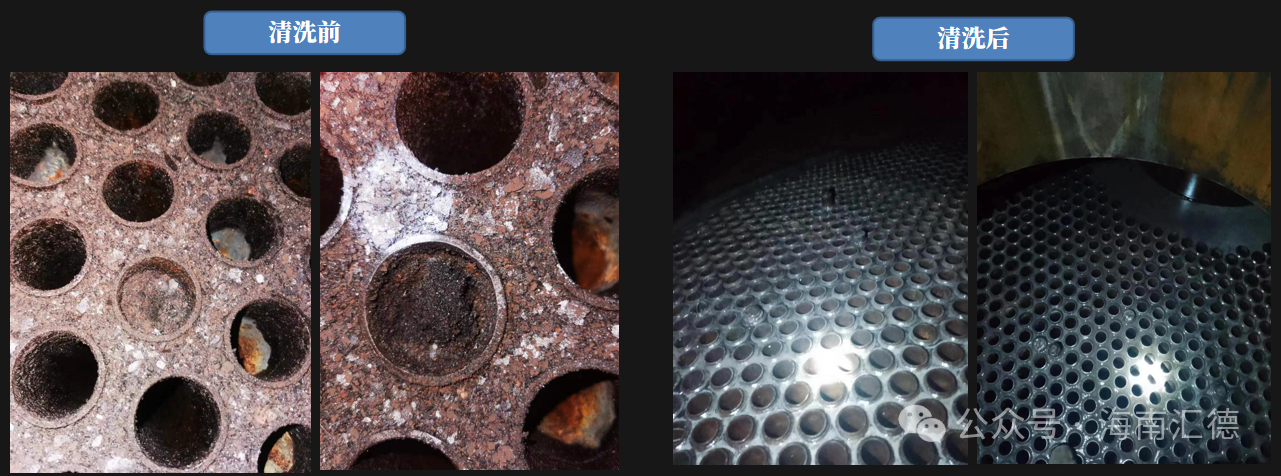

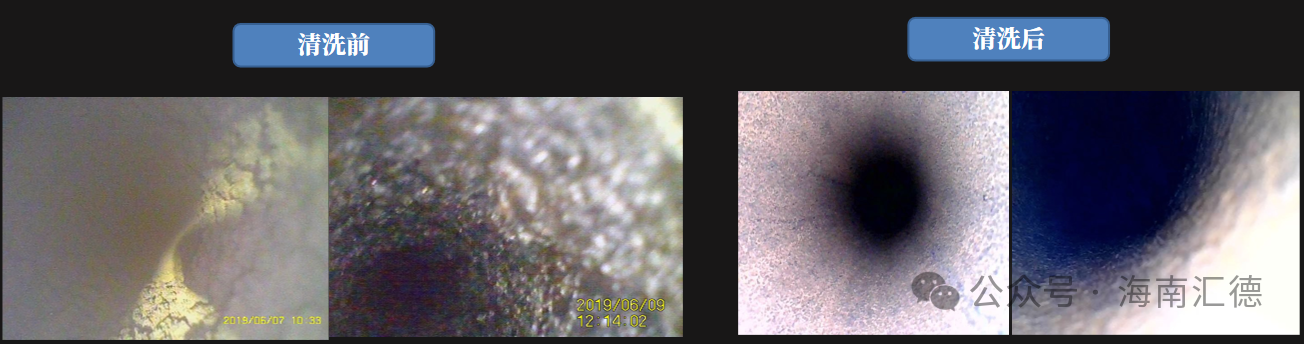

The following pictures show the condition of a typical boiler tube bundle that has not been cleaned and maintained for a long time.

▍Disadvantages of routine cleaning

At present, the cleaning of boiler smoke pipe bundles mainly relies on air duct soot blowing and water gun flushing, but both methods have certain disadvantages:

1. Soot blowing on the air duct can only remove the floating ash on the surface of the smoke pipe, but it is difficult to remove the hard layer of dirt under the floating ash.

2. Water gun flushing is limited by the length of the hard gun barrel and cannot penetrate deep into the tube for effective cleaning. In addition, incomplete cleaning may cause water and soot sulfur to mix, forming sulfides that accelerate pipe wall corrosion.

02

High pressure water jet deep cleaning solution

In order to solve the problem of scale and blockage in boiler tube bundles, our company has introduced industrial cleaning into marine boiler tube bundle cleaning, using imported high-pressure water pumps and different types of nozzles to penetrate deep into the boiler tube bundles for thorough cleaning.

▍Advantages of deep cleaning

Thoroughly remove hard attachments in the pipe;

Completely remove sulfur from the pipe wall, avoiding incomplete sulfur cleaning caused by conventional water flushing during dock repairs. The mixture of water and soot sulfur forms sulfides that accelerate corrosion of the pipe wall;

Complete jobs quickly, reduce downtime and improve production efficiency;

It can be used to clean boiler tube bundles of different shapes and materials, and is flexible in operation. It is also effective in cleaning complex structures.

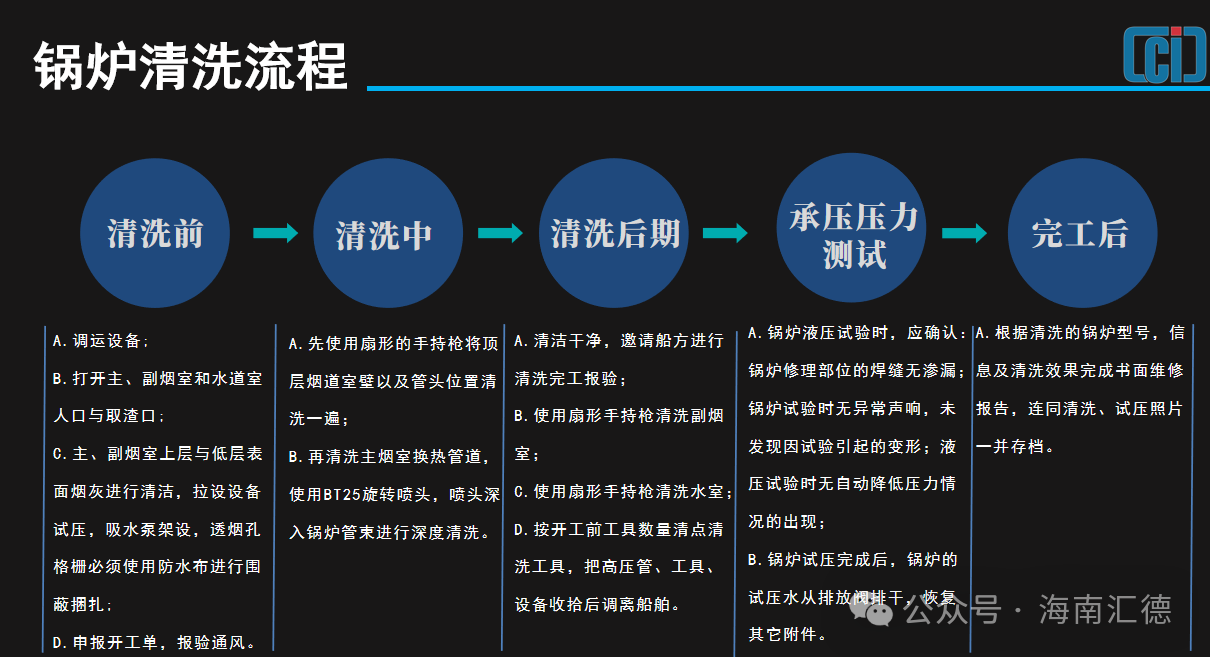

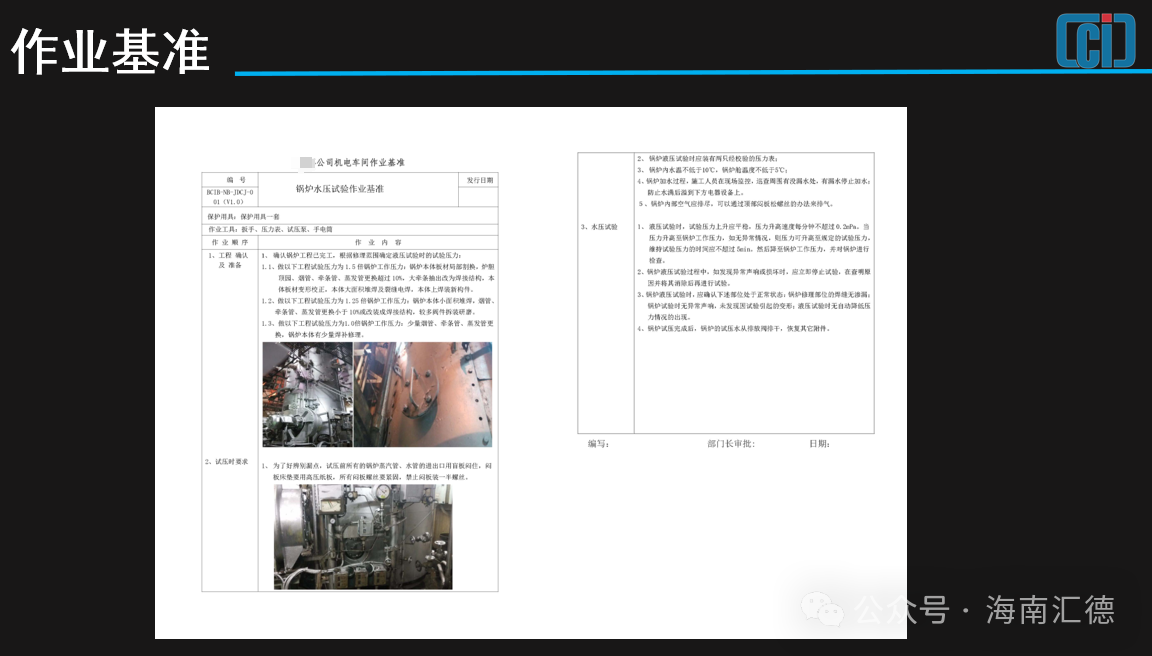

Our company has a complete and professional cleaning process, which has been carefully designed to ensure the efficiency, safety and reliability of cleaning operations, and can meet the strict requirements for cleaning of different types of equipment.

03

Boiler cleaning case

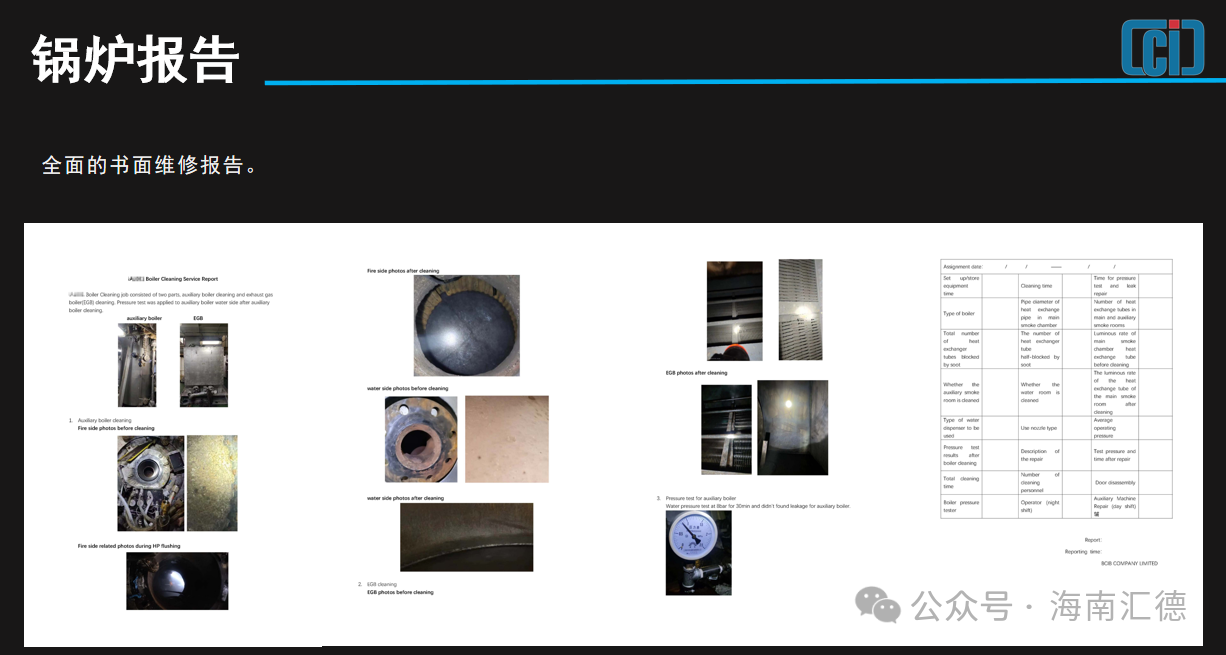

Project: Yong*wheel boiler

Before cleaning: There are 780 pipes in the main smoke chamber, and there are a total of 80 half-blocked and fully-blocked pipes, accounting for 10% of the total number of pipe bundles, and the blockage is dense.

After cleaning: high-pressure water jet was used to clear the blockage, and the effect was good. At the same time, at the request of the shipowner, water jet pipe wall cleaning and maintenance was performed on the auxiliary smoke chamber.

Project: Yong*Hailun Boiler

Before cleaning: The smoke pipe is partially blocked, and a large amount of hard dirt is found attached to the wall of the smoke pipe.

After cleaning: Combined with endoscopic observation, the cleaning effect is good.

Project: annual round boiler

Before cleaning: There are a total of 240 semi-blocked and fully blocked smoke pipes. The plug structure is dense. Before cleaning, the light transmission rate of the main smoke chamber heat exchange pipe is only 50%.

After cleaning: The effect is good. The light transmission rate of the main smoke chamber heat exchange tube is 100% after cleaning.

Project: annual round boiler

Before cleaning: There are a total of 240 semi-blocked and fully blocked smoke pipes. The plug structure is dense. Before cleaning, the light transmission rate of the main smoke chamber heat exchange pipe is only 50%.

After cleaning: The effect is good. The light transmission rate of the main smoke chamber heat exchange tube is 100% after cleaning.