In industrial production, the dirt generated during the operation of equipment will not only increase energy consumption and affect the normal operation of equipment, but also may cause safety accidents and bring unnecessary losses to enterprises. In particular, oil pollution adheres to the surface of the equipment for a long time, which will lead to corrosion of the equipment, and even cause damage to the equipment structure or scrapping.

Therefore, the cleaning process has become an indispensable and important part of modern industrial production. Choosing the right cleaning method is directly related to the cleaning effect, efficiency, safety and environmental protection.

In order to ensure the quality of cleaning, it is important to use an efficient and environmentally friendly cleaning process, and high-pressure water jet cleaning technology is the ideal choice.

高压水射流技术 High-pressure water jet technology

High-pressure water jet technology is an internationally leading high-tech cleaning technology.

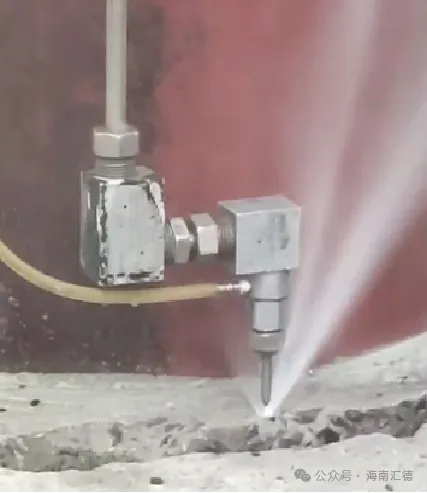

It converts ordinary water into a high-pressure and high-speed water jet through a high-pressure pump, and uses its powerful impact kinetic energy to continuously act on the surface to be cleaned, so that the dirt is removed, so as to achieve efficient cleaning. This technology uses a micro-aperture jet to create a high-speed, micro-water jet, often more than double the Mach number, and is extremely impactful and capable of completing a wide range of complex cleaning tasks.

Areas of application for high-pressure water jet technology

In recent years, high-pressure water jet cleaning technology has developed rapidly and has been widely used in petroleum, chemical, electric power, metallurgy and other industrial fields. Key applications include:

Container cleaning: such as autoclaves, reactors, cooling towers, storage tanks, tankers, etc.

Pipe cleaning: including various equipment pipes, gas pipelines and heat exchangers.

Ship Cleaning: Removes marine life, scale, rust and coating from the hull.

Other fields: It can also be used to clean concrete, resin, pigment, rubber, gypsum, plastic and other materials, and the cleaning effect is remarkable.

Development of high-pressure water jet technology

Japan, Europe and the United States and other developed countries mainly used chemical cleaning methods before the 70s of the 20th century, and began to develop high-pressure water jet cleaning technology at the end of the 70s.

High-pressure water jet technology was introduced into China in the mid-80s of the 20th century and rapidly popularized in the mid-90s. At present, the application of this technology in the field of industrial cleaning in China has exceeded 30%, and it is still growing rapidly. With the continuous improvement of social requirements for cleaning efficiency, cleanliness and environmental protection, the popularization of high-pressure water jet technology has become an inevitable trend.

Advantages of high-pressure water paint removal technology in the ship repair industry

Compared with traditional manual, mechanical and chemical cleaning methods, high-pressure water jet cleaning technology offers the following significant advantages:

Non-destructive substrate: The pressure and flow rate of the water jet can be flexibly adjusted to avoid damaging the surface of the object to be cleaned.

Environmentally friendly and pollution-free: there are no chemicals in the cleaning process, no secondary pollution will be caused, and no additional treatment is required after cleaning.

Adaptable: It can be cleaned with complex shapes or special structures, and is suitable for occasions with narrow spaces or harsh environments.

Efficient and thorough: fast cleaning speed and remarkable results. For example, the sewer pipeline clearance rate is 100%, the heat exchanger cleaning rate is more than 95%, and the boiler descaling rate is more than 95%.

Economical and energy-saving: The cleaning cost is only about 1/3 of that of chemical cleaning, which is an energy-saving equipment.

Versatile: Suitable for a wide range of materials, shapes and types of soil, as long as the water jet can reach the area, it can be thoroughly cleaned.

Environmentally friendly: no harmful substances are discharged, and the dust concentration in the operation area can be reduced during the cleaning process to protect the environment.

Application in heat exchanger and boiler cleaning

●Heat exchanger cleaning

In the production process, heat exchange equipment such as condensers and air preheaters are easy to block, resulting in a decrease in heat exchange efficiency and seriously affecting production. Traditional manual or mechanical clearance methods are inefficient, while high-pressure water jet technology can solve this problem quickly and effectively.

Heat exchangers in different industries have different fouling conditions and require different water pressures. In general, a water pressure of 700 bar is sufficient, but in some special cases, a water pressure of 1400 bar or even 2800 bar may be required.

● Boiler cleaning

Boiler cleaning is divided into two parts: one is to clean the scale and rust in the boiler convection tube, superheater tube, air preheater and water wall tube; The second is the external cleaning of the boiler furnace. The high-pressure water jet technology can completely remove internal fouling, clogging and surface build-up, ensuring efficient boiler operation.

As a professional water treatment cleaning and descaling service company, Hainan Huide Engineering Technology Co., Ltd. has obtained the physical and chemical cleaning qualification issued by the China Industrial Cleaning Association. The company is committed to the research and application of high-pressure water jet cleaning technology, and has a number of domestic leading high-pressure water jet cleaning equipment, which can meet the cleaning needs of various industrial equipment. Its cleaning services have the following features:

Three-dimensional cleaning: comprehensive coverage, no dead ends.

High degree of automation: improve efficiency and reduce labor costs.

Non-destructive surface: Protects the material of the equipment and prolongs the service life.

Strong adaptability: not limited by material and shape, widely used.

Environmental protection and high efficiency: no pollution, high operation efficiency.

High-pressure water jet cleaning technology is becoming the mainstream choice in the field of industrial cleaning due to its high efficiency, environmental protection and economic characteristics. Whether it's heat exchangers, boilers, or other industrial equipment, high-pressure water jet technology provides superior cleaning results, helping companies reduce energy consumption, extend equipment life, and increase productivity. Choosing high-pressure water jet cleaning technology is choosing an efficient, safe and environmentally friendly cleaning solution.

Contact us to learn more about our high-pressure water jet cleaning services to provide professional protection for your equipment!