In the process of alumina production, the problem of pipeline scarring has always been a problem that plagues the efficient production of enterprises, especially the pipeline that transports circulating mother liquor. Due to the long-term accumulation of impurities such as sodium carbonate and silicate in the mother liquor, hard dirt scars will be formed, which are difficult to clean.

The main reasons why it is difficult to clean are as follows:

(1) Long-term deposition of impurities such as sodium carbonate and silicate in the circulating mother liquor form a hard scar with dense structure;

(2) The pipeline is usually long, and the cleaning agent is easy to fail during the transportation process, and it is difficult to reach the depth of the pipeline;

(3) The scarring components are complex, and it is difficult to remove them completely by traditional chemical cleaning methods. In addition, traditional mechanical cleaning and chemical cleaning methods still have disadvantages such as low efficiency, high cost, and environmental pollution, which cannot meet the needs of efficient cleaning.

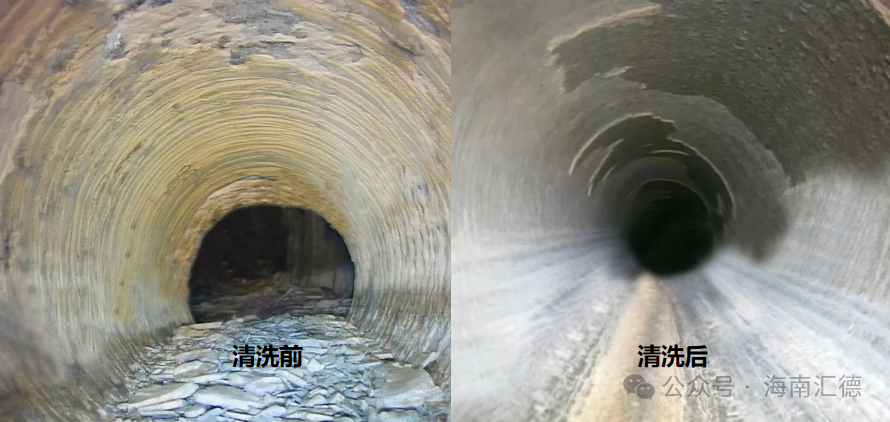

In recent years, high-pressure water jet cleaning technology has been widely used in the field of alumina pipeline cleaning with its advantages of high efficiency, environmental protection and safety, and has achieved remarkable results.

▍Advantages of high-pressure water jet cleaning technology

Efficient cleaning: The high-pressure water jet has extremely high impact energy, which can effectively remove scarring and sediment from the inner wall of the pipe, and the cleaning efficiency is several times higher than that of traditional methods.

Environmentally friendly and pollution-free: water as the medium, no need to add chemicals, no harmful substances will be produced during the cleaning process, and it is environmentally friendly.

Safe and reliable: Non-contact cleaning avoids damage to the inner wall of the pipeline, and reduces the labor intensity and safety risk of the operator.

Wide range of applications: It is suitable for cleaning alumina pipes of various specifications and materials, especially for complex pipe systems and hard-to-reach parts.

▍Application of high-pressure water jet cleaning technology in alumina pipelines

1. Cleaning object:

All kinds of pipelines in the alumina production process, such as mother liquor pipeline, decomposition tank inlet and outlet pipeline, evaporator inlet and outlet pipeline, etc.

Scarring on the inner wall of the pipeline, mainly sodium aluminate solution crystals and aluminum hydroxide deposits.

2. Cleaning process:

Selection of cleaning parameters: According to factors such as pipe material, scar thickness, cleaning distance, etc., reasonable selection of parameters such as water pressure, flow rate, nozzle type, etc.

Cleaning method: handheld cleaning, pipeline automatic cleaning system and other methods can be used to flexibly meet the needs of different scenarios.

Wastewater treatment: The wastewater generated by cleaning needs to be treated by sedimentation and filtration, and then discharged or recycled after reaching the standard.