Oil storage tanks are key facilities used to store oil products in the petrochemical industry. During long-term operation, both the internal and external surfaces of oil storage tanks face challenges from various corrosion factors. The atmosphere, acid rain and other corrosive media in the external environment, such as salt spray, humidity, etc., can cause corrosion to oil storage tanks. At the same time, the oil stored inside, especially the oil containing corrosive components, will continue to corrode the inner wall of the storage tank. If the anti-corrosion treatment of oil storage tanks is not timely or the method is improper, it may lead to serious leakage accidents, which will not only affect the quality and safety of the oil products, but also cause pollution to the environment.

Long-term corrosion will gradually weaken the structural integrity of the oil storage tank, which may eventually lead to equipment damage or even scrapping. In extreme cases, corrosion may also cause safety accidents, threatening personnel and property safety.

01

Tank corrosion type

Tank corrosion is an important issue facing the oilfield industry. It not only affects the service life of the storage tank, but may also pose a threat to the environment and personnel safety. According to on-site investigation and corrosion analysis, storage tank corrosion can be roughly divided into the following types:

●Chemical corrosion: This corrosion mainly occurs on the outer wall of the tank in a dry environment. Although the degree of corrosion is usually mild, due to the large differences in the environments in which oil storage tanks are located, the degree of corrosion will also vary, so generalizations cannot be made.

●Concentration corrosion: This corrosion mainly affects the area below the liquid level on the inner wall of the oil tank, and is caused by the difference in oxygen concentration. The area below the liquid surface may create a more corrosive environment due to lack of oxygen.

●Primary cell corrosion (electrochemical corrosion): This is the most important and serious form of corrosion, which usually occurs at the bottom, wall and top of the tank. Due to the complexity of the internal environment of oil tanks, electrochemical corrosion is very harmful and requires special attention.

●Bacterial corrosion: Corrosion caused by sulfate-reducing bacteria and other bacteria mainly occurs at the bottom of the tank. Corrosive substances produced by bacterial metabolism will accelerate the corrosion process of metals.

●Friction corrosion: This kind of corrosion mainly occurs in the floating expansion and contraction parts of floating roof tanks. As the floating roof moves up and down the liquid level in the tank, it may rub against the tank wall, causing corrosion.

For these different corrosion types, corresponding anti-corrosion measures need to be taken. For example, for electrochemical corrosion and bacterial corrosion, measures such as cathodic protection, use of anti-corrosion coatings, and regular cleaning and maintenance can be taken to reduce the impact of corrosion. For frictional corrosion, the risk can be reduced through the use of wear-resistant materials and improved design.

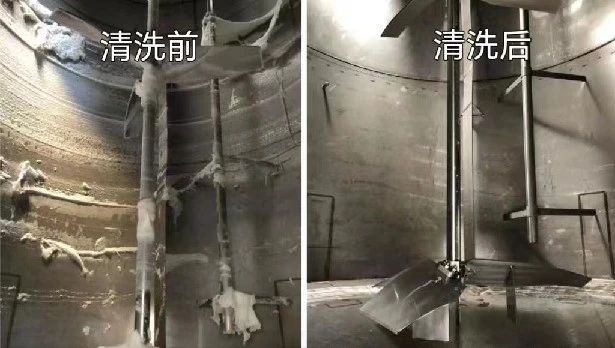

In the anti-corrosion work of oil storage tanks, ensuring that the metal surface of the tank is clean is a crucial step. Cleaning work can not only remove corrosion, rust and aging paint layers on the surface, but also improve the adhesion of the coating surface, thereby enhancing the anti-corrosion effect. The traditional open sandblasting rust removal method has been gradually eliminated due to its high work intensity, harmful health effects and possible environmental pollution.

At present, the most advanced and environmentally friendly cleaning process in China is the high-pressure water jet cleaning process. This process uses the impact of high-pressure water jets to remove dirt and rust from metal surfaces, which is not only highly efficient but also less harmful to operators and the environment.

02

Hainan Huide anti-corrosion technology

BCIB relies on its experience in high-pressure water jet cleaning technology to provide a comprehensive solution for the anti-corrosion of oil storage tanks. These solutions include:

●Automatic high-pressure water cleaning system for storage tanks: Hainan Huide's automatic high-pressure water cleaning system for storage tanks integrates a high-pressure water cleaning mechanism, a three-dimensional rotating nozzle, a traction device and a control operating system, which can realize 360° sealed high-pressure water inside the storage tank. Clean. This automated and mechanized cleaning method greatly improves cleaning efficiency and also ensures the safety of the cleaning process.

●Storage tank rust removal wall-climbing robot: Hainan Huide's storage tank rust removal wall-climbing robot combines high-pressure water jet rust removal technology with a vacuum evacuation solid-liquid separation system, which can effectively remove corrosion and wear without causing corrosion. Remove rust and deposits from the outer wall of the tank. In addition, the vacuum evacuation system can separate and recycle the cleaned waste materials and water without additional manual processing, further improving the environmental protection and efficiency of the operation.